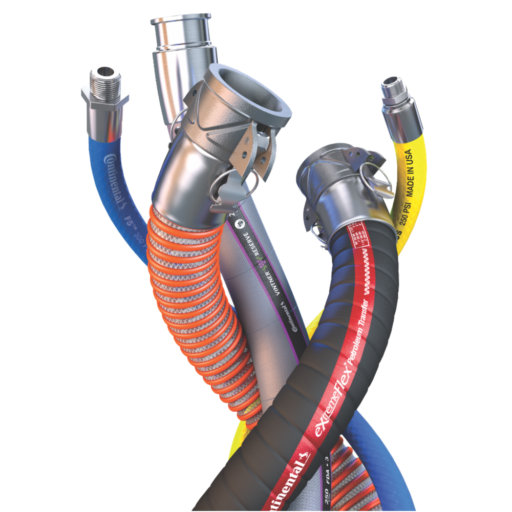

In demanding defense environments, air handling and ventilation ducting must stand up to heat, cold, vibration, and abrasion—without failure. That’s why Flexaust ducting, available through Hampton Rubber, is trusted across naval bases, shipyards, and mobile military installations.

Built in the USA using rugged materials—aluminum, neoprene, fiberglass, PVC, silicone, and more—Flexaust hoses meet the airflow, temperature, and durability requirements of modern military infrastructure. Products like the Springflex Arctic Duct U provide flame-retardant insulation (R‑4), extreme cold resistance (‑40°F), and compression flexibility for tight storage or transport.

But it’s more than the product—it’s the partner. Hampton Rubber’s value comes from decades of experience supporting military and marine operations. We provide:

- ✔️ Specification assistance for MIL, NAVFAC, and shipyard procurement

- ✔️ Custom duct-to-collar assemblies and fitting integration

- ✔️ Quick-turn sourcing and kitting for urgent timelines

- ✔️ In-stock inventory of high-demand Flexaust models

Whether your application is hot exhaust handling or cold air delivery in mobile shelters, Hampton Rubber helps deliver performance you can count on—when downtime isn’t an option.

FAQs

1. What makes Flexaust ducting suitable for military applications?

Flexaust offers heavy-duty, crush- and flex-resistant ducting built in the USA. It’s ideal for pier-side HVAC, exhaust ventilation, confined space air movement, and more.

2. What is the Springflex Arctic Duct U and where is it used?

This insulated, flame-retardant duct is perfect for extreme climates. It’s compressible, operates from ‑40°F to 250°F, and supports high-volume airflow in field shelters or shipboard operations.

3. How does Hampton Rubber add value to Flexaust ducting solutions?

We offer guidance on product selection, military-spec assemblies, and custom end configurations. Plus, we maintain stock and can deliver fast—even when project timelines are tight.

4. Can you supply complete duct systems with fittings?

Yes. We provide fully integrated ducting solutions including collars, clamps, reducers, and support hardware—engineered and assembled for plug-and-play deployment.