Industrial Supply & Hydraulic System Products

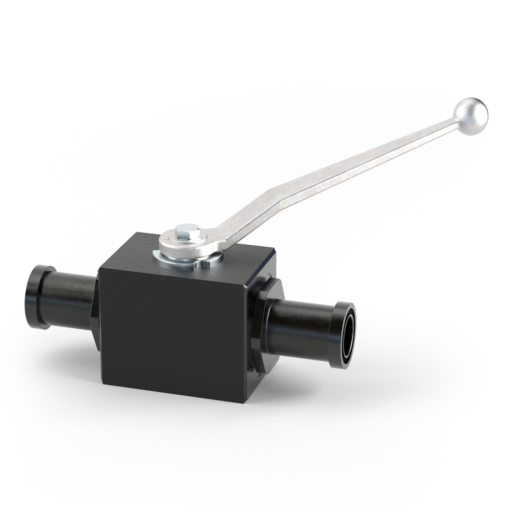

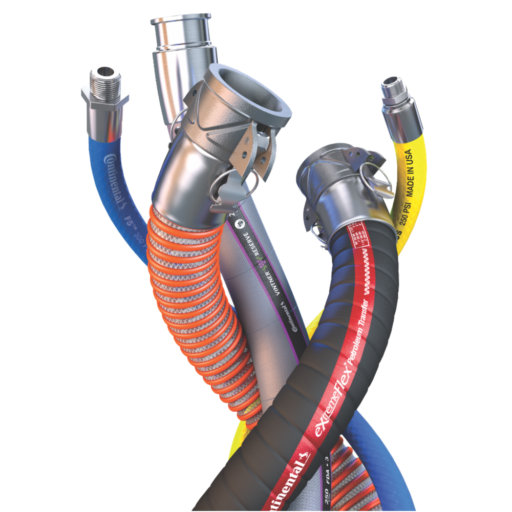

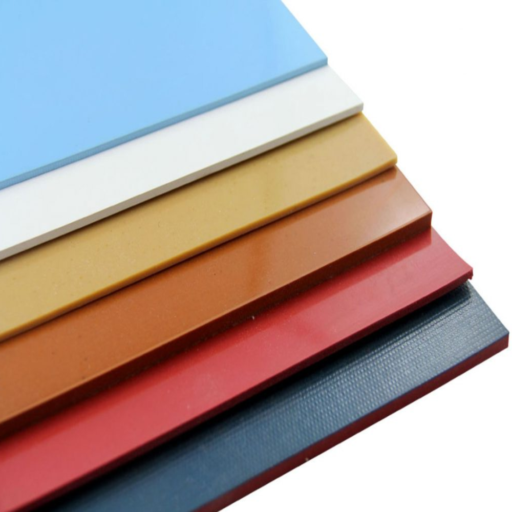

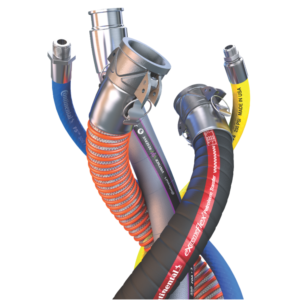

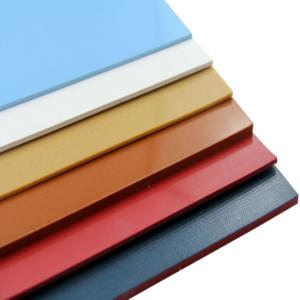

Hampton Rubber Company offers a wide range of industrial products to meet the needs of demanding applications. From industrial and hydraulic hoses to gaskets, sealing products, expansion joints, and power transmission components, our inventory supports industries like marine, military, manufacturing, and energy. We also provide custom fabrication and hose assembly services to match exact specifications. With a focus on performance and durability, our products are designed to improve system reliability and reduce downtime. Whether you’re sourcing fittings, instrumentation, or safety matting, Hampton Rubber delivers trusted solutions backed by expert service and support. Contact us today to find the right fit for your needs.

Don't see what you are looking for?