Hydraulic Hose Assembly Services

Hampton Rubber – Your Trusted Source for Danfoss Aeroquip Hydraulic Hose Solutions

At Hampton Rubber, we provide industry-leading fluid power solutions, offering a comprehensive range of Danfoss Aeroquip hydraulic hoses designed for superior performance, durability, and reliability. Our team is highly trained in hose assembly, following both manufacturer and NAHAD guidelines, ensuring that every hose is crimped and fitted to precise specifications. Hydraulic systems are mission-critical, and choosing the right hose from an experienced, trusted supplier is essential for safety, efficiency, and long-term performance.

Hampton Rubber - Your Source for Aeroquip Hydraulic Hose

Danfoss Aeroquip Hydraulic Hose – Product Highlights

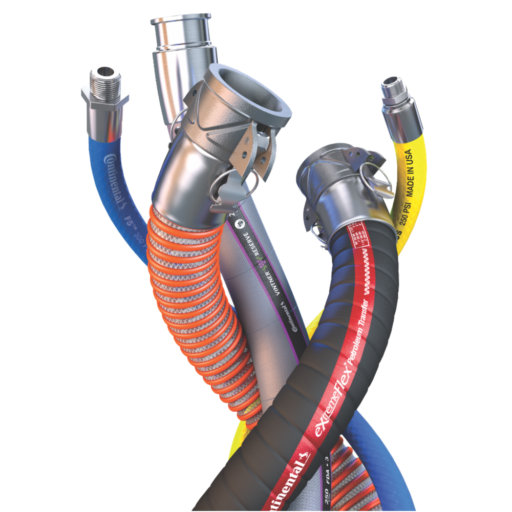

✔ One Wire Hydraulic Hose – A versatile SAE-rated hose designed for medium-pressure hydraulic systems, offering flexibility and abrasion resistance for a variety of industrial and mobile applications.

✔ Two Wire Hydraulic Hose – High-pressure reinforced hose, built with two layers of wire braiding, ensuring superior burst strength and reliability for demanding hydraulic circuits.

✔ Four/Six Wire Spiral Hose – Heavy-duty hose engineered for extreme pressure hydraulic applications, featuring multiple layers of spiral-wound reinforcement to withstand high impulse cycles and heavy loads.

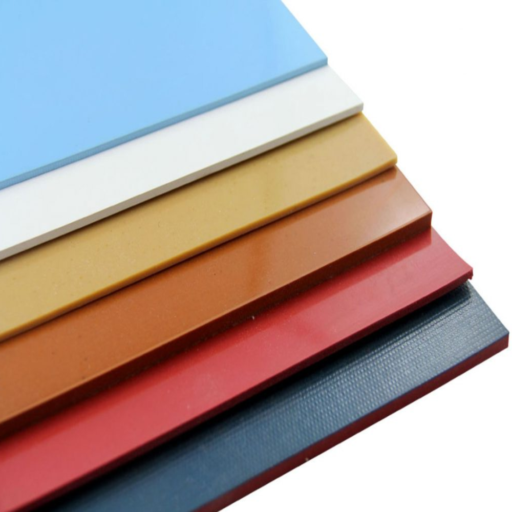

✔ Thermoplastic Hydraulic Hose – Lightweight and highly flexible hose with enhanced chemical resistance, ideal for mobile equipment, aerial lifts, and industrial automation systems.

✔ Suction & Low Pressure Return Hose – Designed for fluid suction and return line applications, featuring reinforced construction to prevent collapse and kinking under vacuum conditions.

✔ Stainless Steel Braided PTFE Hose – High-temperature, chemically resistant hose, offering exceptional flexibility and durability for hydraulic, chemical transfer, and steam applications.

✔ Transportation Hoses – DOT-approved hydraulic hoses for brake systems, fuel lines, and air brake applications in heavy-duty transportation and fleet operations.

✔ AQP High Performance Hose – Engineered with Danfoss Aeroquip’s patented AQP elastomer, this hose offers exceptional durability, oil resistance, and temperature stability, outperforming standard rubber hoses in demanding hydraulic applications.

✔ Danfoss Mil-Spec Hose – Military-grade hydraulic hoses built to meet strict MIL-SPEC requirements, ensuring reliable performance in defense, aerospace, and government applications.

Precision-Assembled Hydraulic Hoses – Built for Performance

At Hampton Rubber, our hydraulic hose assemblies are manufactured to exacting standards, ensuring leak-proof connections and long-lasting performance. Whether you need a single replacement hose or a bulk order for industrial operations, we provide:

✅ Expertly trained staff following NAHAD and OEM assembly guidelines

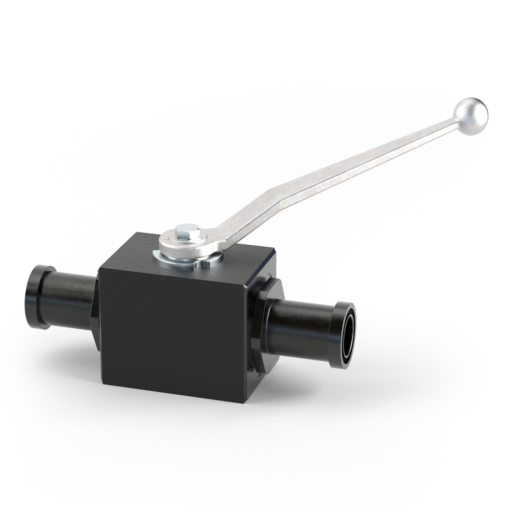

✅ Precision crimping and fitting services for reliable installations

✅ Extensive inventory of Danfoss Aeroquip hydraulic hoses & fittings

✅ Fast turnaround and responsive customer support

Don’t second guess your hydraulic hose supplier. Contact Hampton Rubber today for superior Danfoss Aeroquip hydraulic hose solutions you can trust!

Trained Hydraulic Assembly Staff

Why Choosing a Company with Trained Employees for Hydraulic Hose Assembly Matters

When it comes to hydraulic hose assembly, selecting a company with trained professionals ensures safety, reliability, and long-term efficiency in your hydraulic systems. Properly assembled hoses prevent leaks, reduce downtime, and extend equipment lifespan, making them essential for high-pressure applications in industrial, construction, marine, and transportation sectors. Trained professionals follow strict industry guidelines, use precise crimping techniques, and ensure system compatibility, reducing the risk of catastrophic failures.

Key Benefits of Using a Professional Hydraulic Hose Supplier

✔ Expertise & Precision – Trained professionals ensure hoses are accurately measured, cut, and crimped, meeting precise OEM and industry standards.

✔ Compliance with Industry Standards – Reputable suppliers follow SAE, ISO, and OEM specifications for optimal performance and safety.

✔ Minimized Downtime & Failures – Properly assembled hoses reduce the risk of leaks, bursts, and premature wear, keeping operations running efficiently.

✔ Access to Quality Materials – Professional suppliers source hoses from top-tier manufacturers, ensuring durability, flexibility, and pressure resistance.

✔ Customization for Your Needs – Get custom-built hose assemblies tailored to your specific pressure ratings, lengths, fittings, and application demands.

FAQs: Selecting the Right Hydraulic Hose Supplier

1. What should I look for in a hydraulic hose supplier?

✔ Choose a supplier with certified, trained technicians, high-quality products, fast turnaround times, and excellent customer support.

2. Why is proper hose assembly important?

✔ Incorrect assembly can lead to leaks, pressure loss, equipment failure, or even safety hazards in high-pressure environments.

3. Do all hydraulic hoses need to be crimped?

✔ Most high-pressure hydraulic hoses require precision crimping for a secure, leak-proof connection. Some low-pressure hoses may use clamps.

4. How do I know if a supplier uses high-quality materials?

✔ Check if they offer hoses from reputable brands, comply with industry standards, and provide certifications or warranties.

5. Can I get a custom hydraulic hose assembly?

✔ Yes! Professional suppliers can customize hoses based on pressure ratings, lengths, fittings, and application needs.

6. How often should hydraulic hoses be replaced?

✔ Hoses should be inspected regularly and replaced based on wear, manufacturer recommendations, or when visible damage is present.

7. Does a supplier’s location matter?

✔ Yes! Choosing a local supplier with fast turnaround times ensures quick replacements and reduces downtime.

Choose Hampton Rubber for Expert Hydraulic Hose Assembly

At Hampton Rubber, we ensure that every hydraulic hose assembly is built to meet and exceed industry standards. Our team of trained professionals follows manufacturer and NAHAD guidelines, guaranteeing that every hose is precision-crimped, fitted, and tested for leak-free performance.

Don’t take risks with an inexperienced supplier. Contact Hampton Rubber today for reliable, high-performance hydraulic hose solutions!