Waterjet Cutting Services

Precision Waterjet Cutting Services at Hampton Rubber

At Hampton Rubber, we offer best-in-class waterjet cutting services, providing precision-cut gaskets and custom rubber components with 100% repeatability and flawless accuracy. Whether you provide us with a sample, CAD drawing, or detailed specifications, our state-of-the-art waterjet technology ensures consistent, high-quality results—every time.

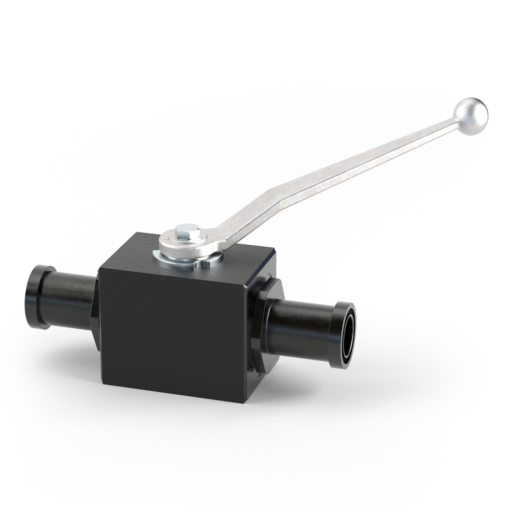

Using 60,000 psi water pressure, we can finely cut a variety of materials with no heat distortion or material stress, making it the perfect solution for custom sealing applications and complex part designs. Our advanced waterjet cutting capabilities allow us to process:

✔ Rubber – Including Neoprene, EPDM, Silicone, Viton, and other elastomers

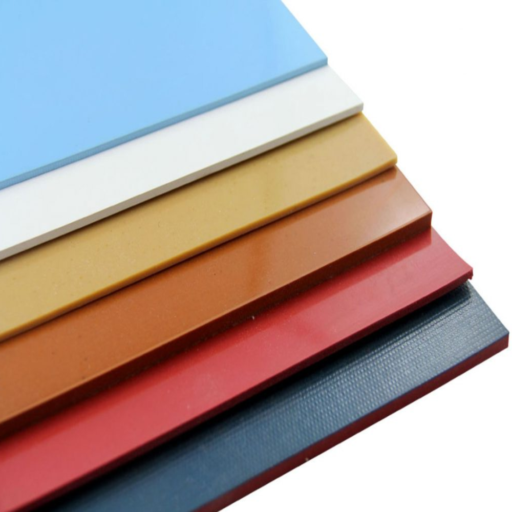

✔ Gasket Sheet Material – Compressed fiber, PTFE, graphite, and other specialty sealing materials

✔ Plastic & Polymer Sheets – ABS, HDPE, UHMW, and more

✔ Paper & Soft Materials – Non-metallic insulation, fiberboard, and composite materials

✔ And much more

With Hampton Rubber’s precision waterjet cutting, you get clean, accurate, and efficient cuts tailored to your exact application needs. Whether you need single prototypes or large-scale production runs, our cutting-edge technology ensures that your parts are made to the highest quality standards with minimal waste and fast turnaround times.

Waterjet Cutting

Hampton Rubber: High-Performance Water Jetting Solutions

At Hampton Rubber, we provide high-performance water jetting solutions designed for industrial cleaning, surface preparation, and material removal. Our expert team ensures safe, efficient, and precise water jetting services, maximizing productivity while minimizing downtime. Whether you need high-pressure cleaning, pipe and tube descaling, or hydro-demolition, we have the cutting-edge equipment and expertise to get the job done right.

Common Questions About Water Jetting

What is water jetting?

Water jetting, also known as hydroblasting, is a high-pressure water cleaning method used to remove debris, coatings, scale, and contaminants from surfaces, pipes, and equipment. It is a non-abrasive, environmentally friendly, and highly effective solution for industrial maintenance and cleaning.

What are the benefits of using water jetting?

✔ Superior Cleaning Power – Removes stubborn dirt, rust, coatings, and blockages more effectively than traditional methods.

✔ Non-Damaging – Does not generate heat or mechanical force, preserving the integrity of surfaces and materials.

✔ Eco-Friendly – Uses only water, eliminating the need for harsh chemicals or hazardous solvents.

✔ Increased Safety – Reduces airborne contaminants and minimizes operator exposure to hazardous substances.

✔ Versatility – Suitable for various surfaces, including concrete, metal, and industrial machinery.

Industries That Benefit from Water Jetting Services

Water jetting is widely used across multiple industries, including:

✔ Construction & Demolition – Removing coatings, concrete, and rust safely and efficiently.

✔ Manufacturing & Industrial Plants – Cleaning heat exchangers, tanks, and industrial piping.

✔ Oil & Gas – Clearing blockages and descaling pipelines for optimal flow efficiency.

✔ Food Processing & Pharmaceuticals – Sanitizing surfaces without chemicals, meeting strict regulatory standards.

✔ Recycling & Waste Management – Clearing debris, sludge, and clogged equipment to improve operations.

Water Jetting Services at Hampton Rubber

We offer a full range of high-pressure water jetting solutions, including:

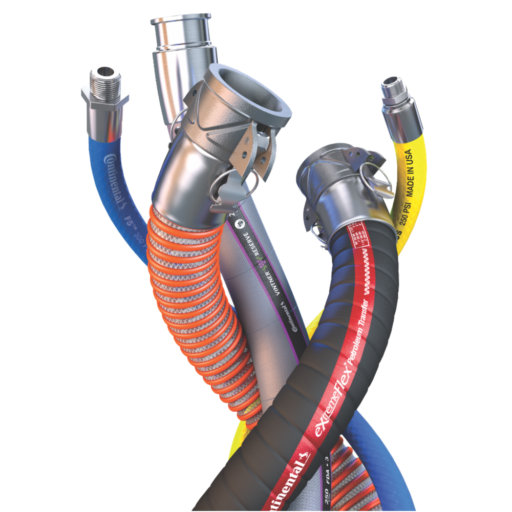

✔ Pipe & Tube Cleaning – Removes scale, sludge, and obstructions from industrial piping and process systems.

✔ Surface Preparation – Strips paint, coatings, and corrosion without damaging the base material.

✔ Heat Exchanger & Condenser Cleaning – Restores efficiency by eliminating buildup and deposits.

✔ Tank & Vessel Cleaning – Ensures a thorough, chemical-free clean for storage and processing tanks.

✔ Concrete Hydro-Demolition – Precision removal of concrete and coatings without vibrations or structural damage.

How Does Water Jetting Compare to Traditional Cleaning Methods?

Unlike grinding, sanding, or chemical cleaning, water jetting offers:

✔ Greater Efficiency – Faster and more thorough removal of contaminants.

✔ Less Equipment Wear – Non-abrasive cleaning preserves surfaces and materials.

✔ Environmentally Safe – No toxic byproducts or secondary waste.

✔ Precision Cleaning – Targets specific areas without affecting surrounding materials.

FAQs About Water Jetting

1. Is water jetting safe for all surfaces?

✔ Yes! Water jetting is highly customizable, allowing pressure adjustments and nozzle variations to clean both delicate and heavy-duty surfaces safely.

2. Can Hampton Rubber provide on-site water jetting services?

✔ Absolutely! Our mobile water jetting units allow us to perform on-site industrial cleaning and maintenance at manufacturing plants, construction sites, and processing facilities.

3. How often should industrial equipment be cleaned with water jetting?

✔ The frequency depends on the application and industry, but regular cleaning can:

• Extend equipment lifespan

• Improve system efficiency

• Prevent costly downtime due to blockages or buildup

✔ We can create a custom maintenance schedule tailored to your specific needs.

Hampton Rubber: Your Trusted Water Jetting Service Provider

With state-of-the-art equipment, experienced technicians, and on-site service capabilities, Hampton Rubber delivers powerful and efficient water jetting solutions for a wide range of industrial applications.

Need high-pressure cleaning? Contact Hampton Rubber today to schedule a consultation!