VA Welding Services

At Hampton Rubber, we are committed to employing full-time welders accredited by ASME Section IX, each bringing decades of experience in metal hose manufacturing. The importance of using ASME-certified welders in metal hose fabrication cannot be overstated, as it ensures unmatched quality, reliability, and safety in every assembly we produce. ASME certification is a rigorous process that requires extensive testing and evaluation of a welder’s skills and expertise, guaranteeing that all welds meet strict industry standards. By choosing Hampton Rubber, you’re assured that your metal hose assemblies are fabricated with the highest level of precision and compliance, making us the trusted choice for mission-critical applications.

OEM Metal Hoses

OEM Metal Hose Solutions – Hampton Rubber

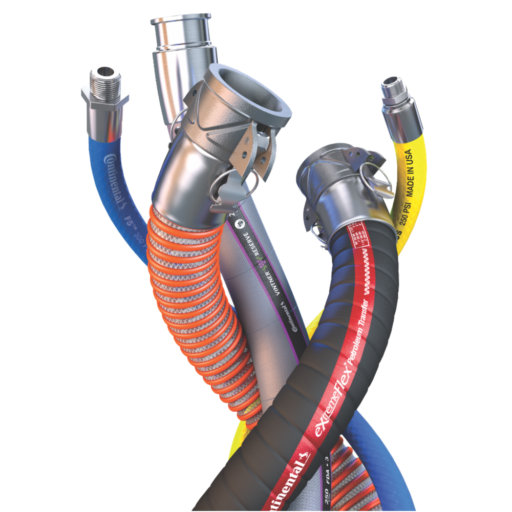

Original Equipment Manufacturers (OEMs) demand high-quality metal hoses that meet strict safety and performance standards for flexibility, high-pressure resistance, and durability in extreme environments. At Hampton Rubber, we provide precision-engineered metal hoses tailored for OEM applications, ensuring reliability in the most demanding conditions.

Best Applications for Metal Hoses in Equipment Design

Metal hoses are widely used in:

✔ High-temperature exhaust systems

✔ Cryogenic fluid transfer

✔ Hydraulic and pneumatic systems

✔ Aerospace and automotive applications

✔ Industrial and chemical processing plants

How to Choose the Right Metal Hose for Your OEM Application

Use the STAMPED method to determine the ideal hose:

✔ Size – Inside diameter (ID), outside diameter (OD), and overall length.

✔ Temperature – Maximum and minimum operating temperatures.

✔ Application – Movement, vibration, pressure, and flexibility requirements.

✔ Media – Type of fluid or gas being transferred.

✔ Pressure – Working pressure, surge, and burst ratings.

✔ Ends – Fittings and attachment methods.

✔ Delivery – Lead times, compliance, and packaging requirements.

Metal Hose Maintenance Best Practices

✔ Regular inspections – Check for cracks, leaks, or corrosion.

✔ Proper routing – Prevent excessive bending, kinking, or strain.

✔ Periodic cleaning – Remove contaminants that could impact performance.

✔ Scheduled replacement – Follow recommended service life intervals to avoid failures.

At Hampton Rubber, we provide OEM metal hoses designed for longevity, efficiency, and compliance with industry standards. Whether for high-heat, cryogenic, or high-pressure applications, our ASME-certified welding and fabrication ensure top-tier performance in every hose assembly.

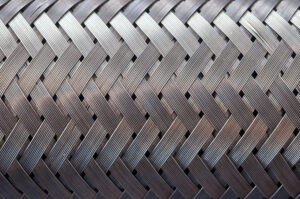

Single or Double Braided Metal Hose

Single vs. Double Braided Metal Hoses – Choosing the Right Option

When selecting a metal hose, the choice between single or double braiding depends on pressure requirements, flexibility, and durability for your specific application. At Hampton Rubber, we provide expertly crafted metal hoses to meet the demands of industrial, marine, and high-pressure environments.

Single vs. Double Braided Metal Hoses

✔ Single Braided Hose – Provides reinforcement against internal pressure while maintaining maximum flexibility. Ideal for moderate-pressure applications where maneuverability and ease of installation are key.

✔ Double Braided Hose – Offers enhanced strength and pressure resistance, making it ideal for high-pressure applications or environments with frequent movement and vibration.

FAQs: Choosing the Right Braiding for Your Metal Hose

1. When should I use a double-braided hose instead of a single-braided one?

✔ Use double braiding for high-pressure fluids or gases or when added durability is required for extended service life.

2. Does double braiding reduce flexibility?

✔ Yes, double-braided hoses are typically less flexible due to the additional reinforcement. If maximum flexibility is needed, a single-braided hose may be the better option.

3. How does braiding affect pressure ratings?

✔ Double-braided hoses can handle significantly higher pressures than single-braided hoses, making them essential for steam, hydraulic, and other high-pressure industrial applications.

At Hampton Rubber, we ensure that every metal hose assembly is built to meet your exact specifications, providing maximum reliability, performance, and safety in demanding applications. Whether you need single or double-braided metal hoses, our ASME-certified welding and fabrication guarantee superior quality and durability.

With Metal Hose You Can Connect A Variety of Fittings

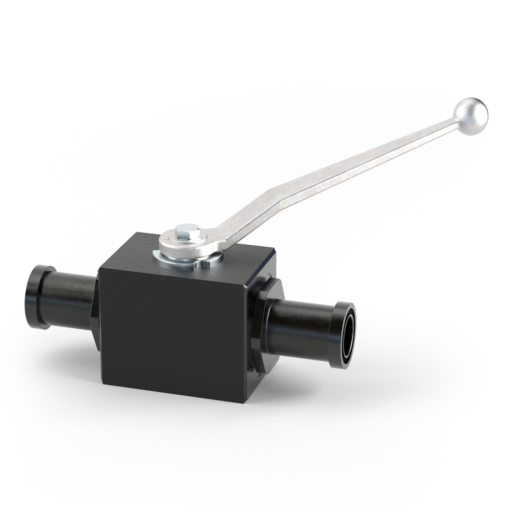

Metal Hose Coupling Options – Choosing the Right Fit

Selecting the right coupling for a welded metal hose depends on factors such as application, pressure, temperature, and fluid compatibility. One of the key advantages of metal hoses is the ability to weld metal couplings directly to the hose, ensuring strong, leak-proof connections for demanding industrial applications.

Common Coupling Types for Metal Hoses

✔ Flanged Couplings – Designed for high-pressure applications, allowing for easy assembly and disassembly.

✔ Threaded (NPT/BSP) Couplings – Used for secure, threaded connections in fluid and gas systems.

✔ Hydraulic Couplings (Including JIC) – Ideal for high-pressure applications, sealing with a mechanical JIC flare.

✔ Cam & Groove Couplings – Quick-connect fittings that allow for fast attachment and detachment, commonly used in industrial and fuel transfer applications.

✔ Tri-Clamp Couplings – Found in sanitary applications, such as food, beverage, and pharmaceutical processing, ensuring easy cleaning and compliance.

✔ Weld Nipple Couplings – Provide a permanent, high-strength connection, making them ideal for extreme conditions and high-pressure environments.

FAQs: Selecting the Right Coupling

1. Which metal coupling is best for high-pressure applications?

✔ Flanged or weld nipple couplings are ideal for high-pressure environments, ensuring a secure, leak-proof seal.

2. What type of coupling is best for quick connections?

✔ Cam & Groove couplings allow for fast attachment and detachment without the need for tools, making them ideal for frequent connection changes.

3. How do I ensure compatibility between the coupling and hose material?

✔ Always match the coupling material (e.g., stainless steel, carbon steel, or specialty alloys) with the hose material to prevent corrosion and ensure long-term structural integrity.

At Hampton Rubber, we provide a full range of precision-welded metal hoses and couplings, ensuring maximum durability, efficiency, and performance for your industrial applications. Whether you need high-pressure, sanitary, or quick-connect couplings, we offer expert solutions tailored to your needs.